A High-Quality Thin Film CadTel Module Made in America, for America.

Series 7 modules combine First Solar’s thin film cadmium telluride (CadTel) technology with a larger form factor and an innovative new back rail mounting system to deliver improved efficiency, enhanced installation velocity, and unmatched lifetime energy performance for utility-scale PV projects. Developed in close collaboration with EPCs, structure and component providers, Series 7 modules are optimized for both form and function. Series 7 TR1 is Made in America exclusively for the US utility-scale market and further enhances lifetime energy for your large-scale projects.

Download the Series 7 TR1 Datasheet

Up to 540Watts

Up to 19.3%Efficiency

30 YearLinear Performance Warranty

0.3%Warranted Annual Degradation Rate

Delivering Unmatched Value and Innovation

Larger Form Factor

More watts per install operation for lower BOS costsBack Rail Mounting Design

Up to 20% faster installation velocity vs. Series 6Frameless Design

Improves soiling and snow sheddingMore Lifetime Energy per Nameplate Watt

Industry’s best warranted annual degradation rate: 0.3%Industry’s Only Cell Cracking Warranty

Immune to and warranted against power loss from cell crackingExceptional Performance

Superior temperature coefficient, spectral and shading responseUnrivaled Quality and Reliability

Singular manufacturing process with 100% QA/QC traceabilityLeading Environmental Profile

Lowest carbon footprint, water footprint, and energy payback timeMade Responsibly in America

Comprehensive supply chain management with zero tolerance for forced labor

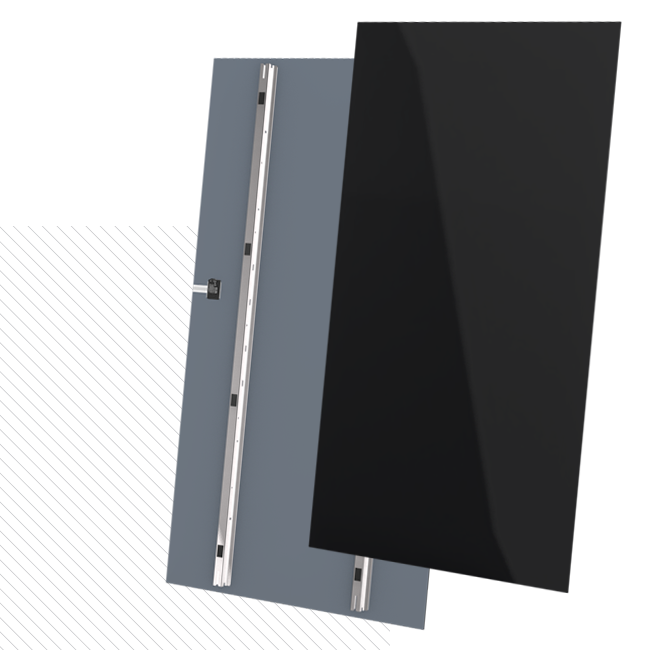

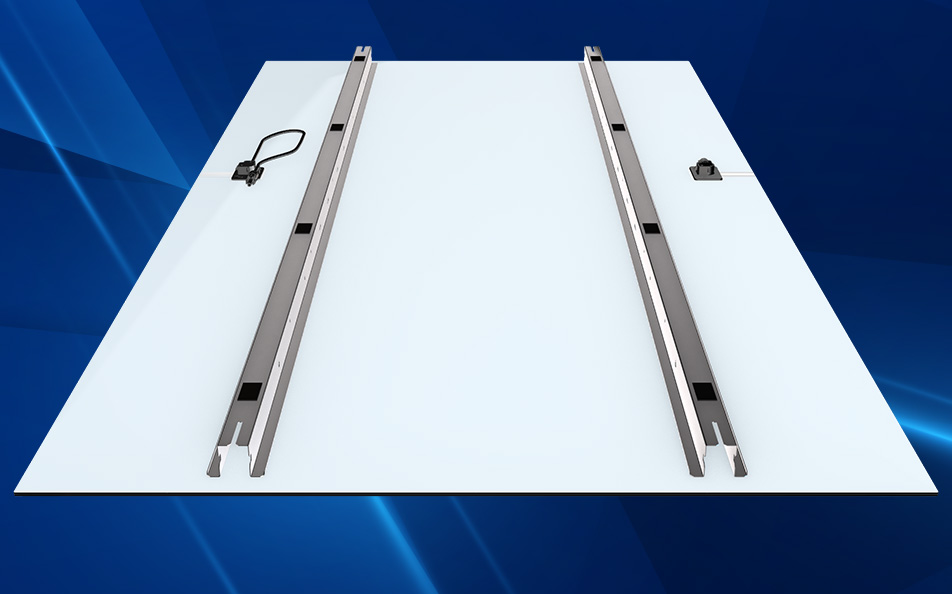

Innovative Back Rail Mounting System

The Series 7 TR1 has galvanized steel back rails and next generation mounting methods will provide easier and quicker field operations resulting in up to 20% faster installation velocity, and up to 15% lower BOS costs vs. Series 6.

The added strength of galvanized steel allows Series 7 TR1 modules to be mounted closer to the center of rotation on a tracker, improving the mechanical efficiency of the motors and dampeners. This can significantly reduce BOS costs by enabling longer tracker rows for more watts per motor, dampener and torque tube.

Larger Module Form Factor

First Solar’s proprietary manufacturing process and CadTel technology allow more form factor flexibility because it is not constrained by industry standard cell or wafer sizes. Along with the added strength and rigidity of galvanized steel back rails, the 1215mm x 2300mm module design optimizes form and function without fear of power loss from cell cracking or other performance-related issues prevalent in crystalline silicon modules.

More Lifetime Energy per Nameplate Watt

Series 7 modules will feature the industry’s best 0.3% warranty-backed annual degradation rate, and boasts a superior temperature coefficient, spectral and shading response – delivering more lifetime energy per installed watt compared to leading bifacial crystalline silicon PV panels.

A Collaborative Process for Success

From day one, First Solar’s product engineering team has worked in deep collaboration with leading EPCs, structure and component providers to create a module that is part of an integrated system solution. By sharing designs and incorporating feedback from industry partners, First Solar has designed a module that is truly optimized for form, function, and cost.